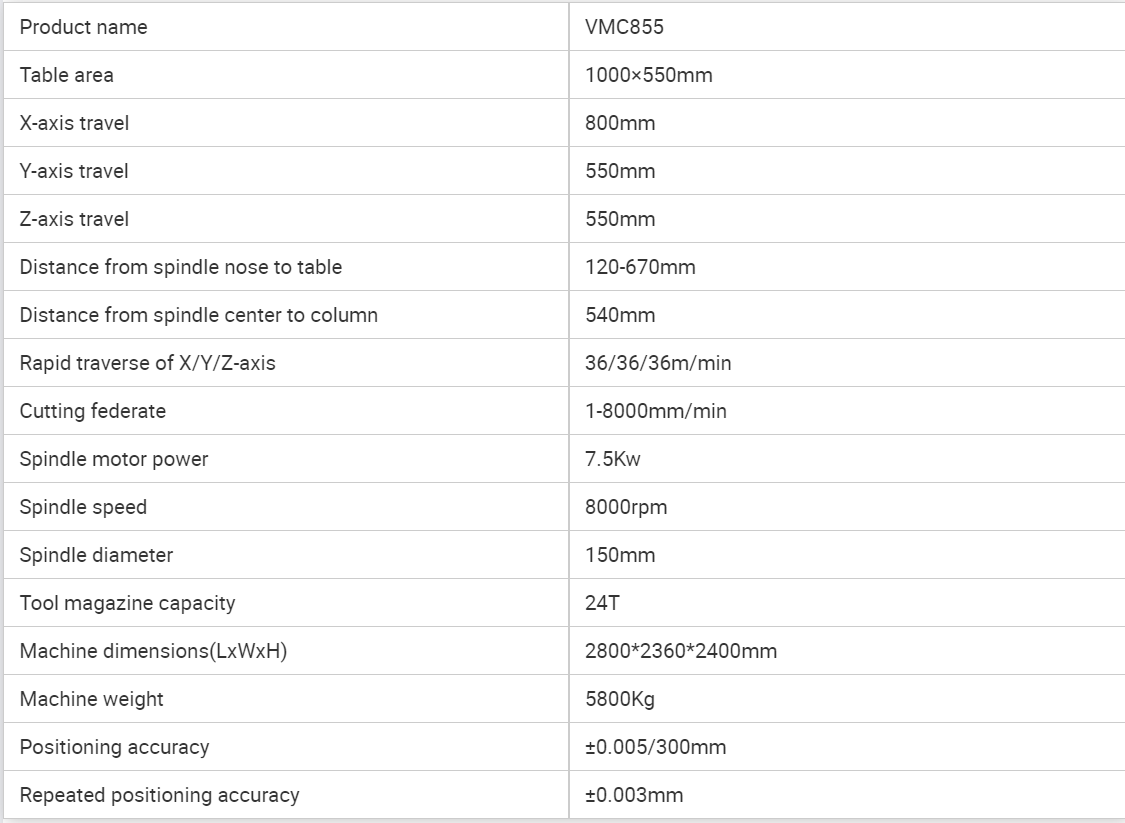

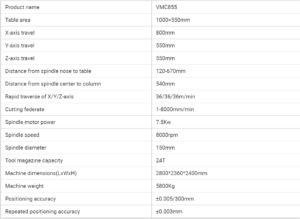

VMC855Machining Center

CNC Milling Machine Vertical Machining Center Made in Chinahot sale vmc855 spindle taper bt40

1. Product introduction and usage

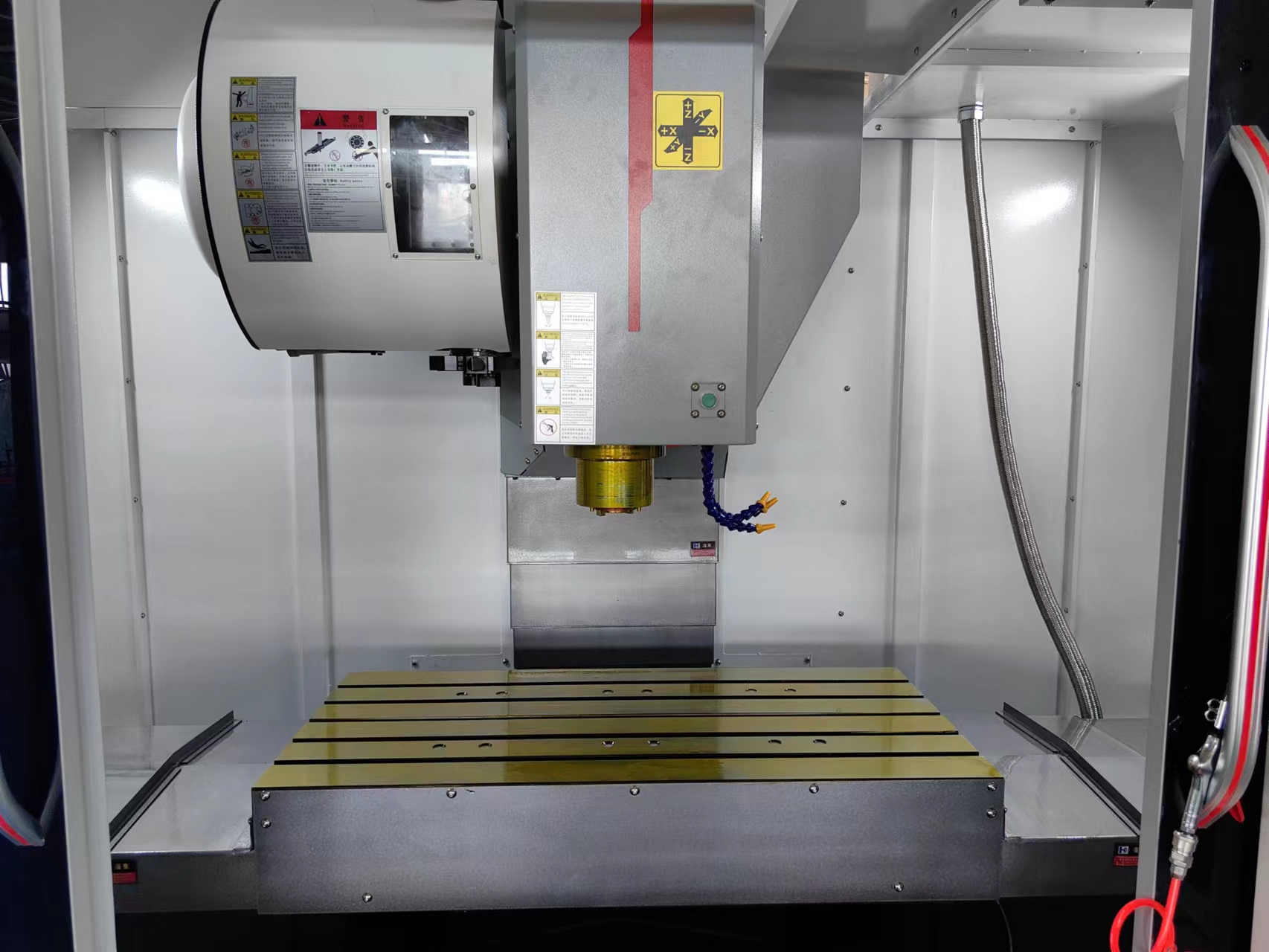

This product is a vertical machining center with three-axis servo direct control of X, Y, and Z. The three axes are all steel ball rolling linear guides. The guide rails have large load, wide span, high precision, compact and reasonable structure and dimensions, and the main axis is servo The motor is driven via a timing belt. It can realize one-time clamping of various complex parts such as disks, plates, shells, cams, and molds, and can complete various processes such as drilling, milling, boring, expanding, reaming, and rigid tapping. It is suitable for many varieties, The production of small and medium-sized batches of products can meet the processing of complex and high-precision parts. It can be equipped with a fourth rotating axis to meet the processing requirements of special parts.

2. Main structural features

1. The main basic parts such as base, slide seat, workbench, column, spindle box, etc. are made of high-strength cast iron; the base is a box-type structure, and the compact and reasonable symmetrical rib structure ensures the high rigidity and bending resistance of the basic parts. Performance; A-shaped bridge-spanning columns and internal grid-like ribs effectively ensure the rigidity and accuracy during strong Z-axis cutting; the basic parts are made of resin sand and have undergone aging treatment, which guarantees the stability of the long-term performance of the machine tool. .

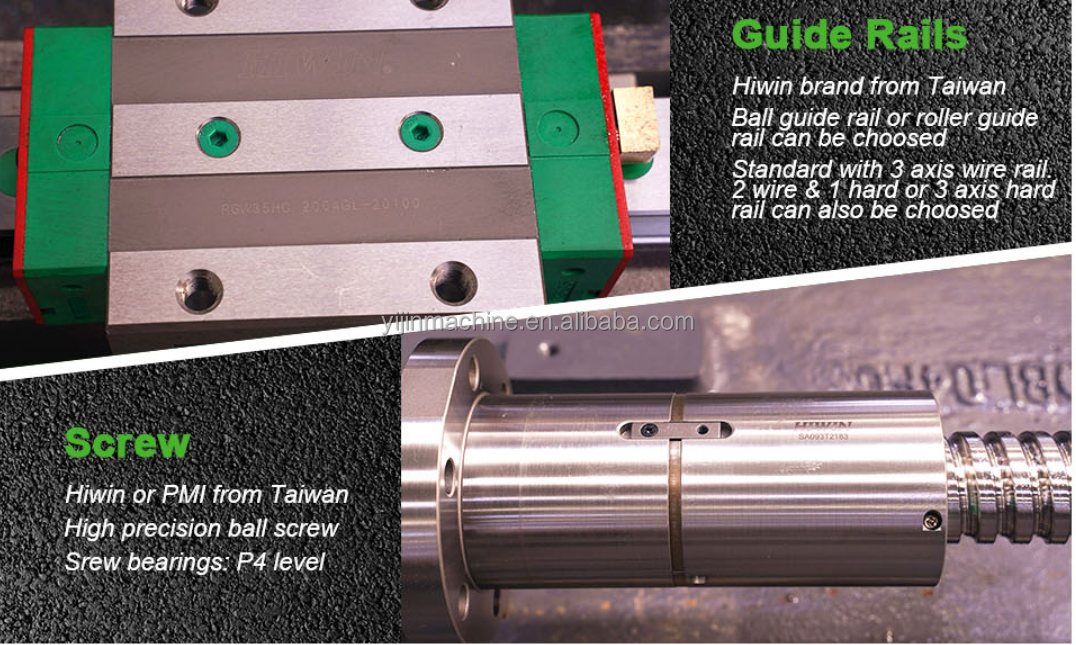

2. The X/Y/Z guide rails are all heavy-duty 35 linear roller guides, which have the characteristics of fast speed, high rigidity, low friction, low noise, low temperature rise changes, etc., and cooperate with automatic forced lubrication to improve the accuracy and life of the machine tool;

3. The Z-direction nitrogen balance system ensures smooth and stable movement of the spindle box; the Z-direction drive motor has a power-off braking device;

4. The feeds in the three directions of The feed servo motor directly transmits power to the high-precision ball screw without backlash, ensuring the positioning accuracy and synchronization of the machine tool;

Reviews

There are no reviews yet.