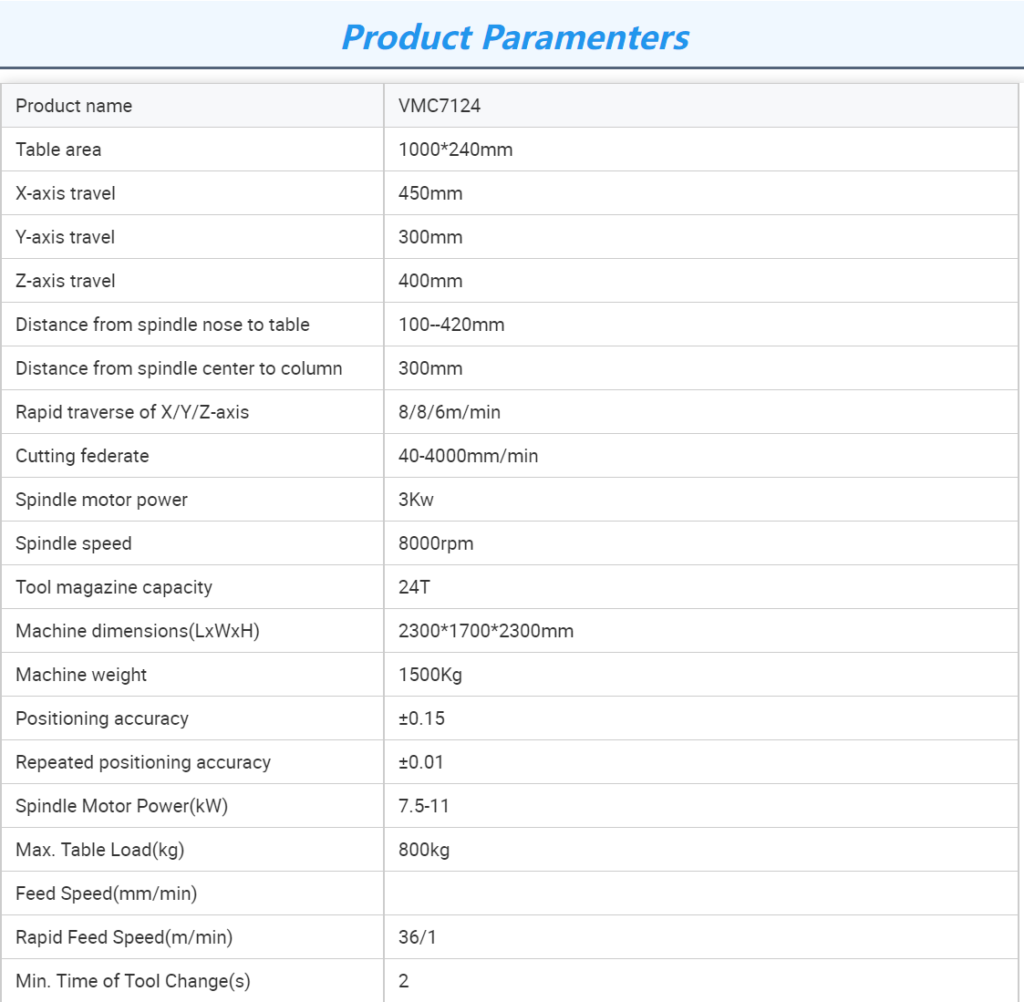

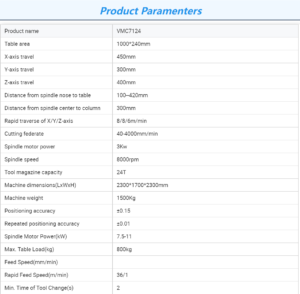

Multifunctional machining center CNC processing customized high precision vmc7124

1.Product Introduction and Usage

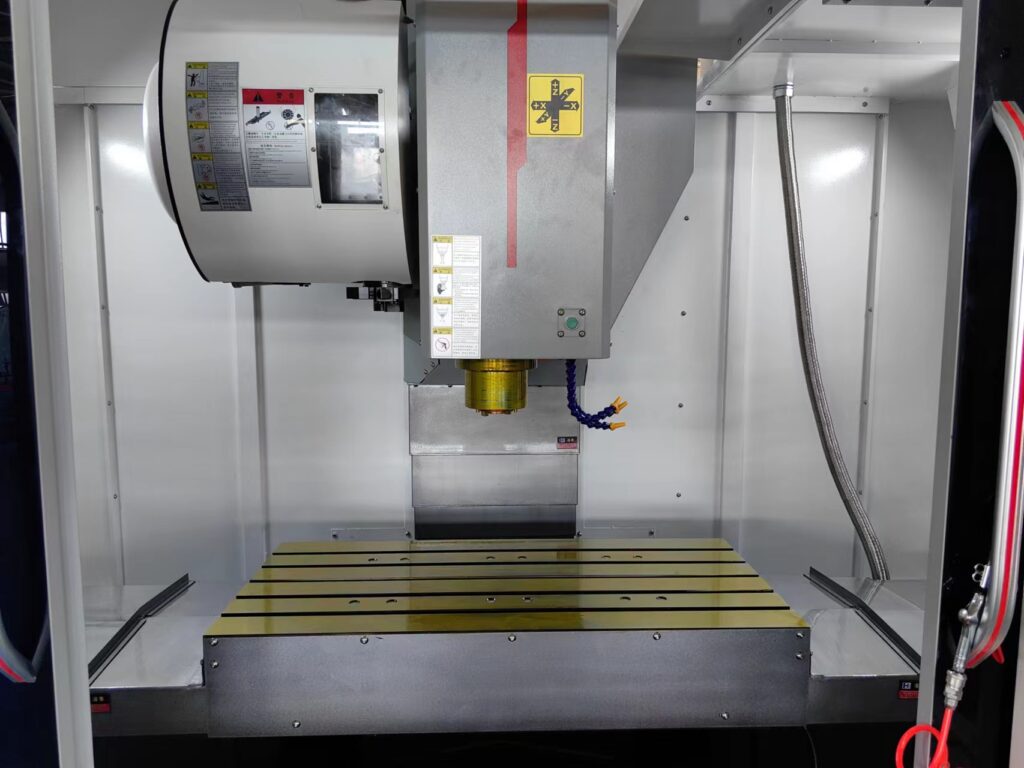

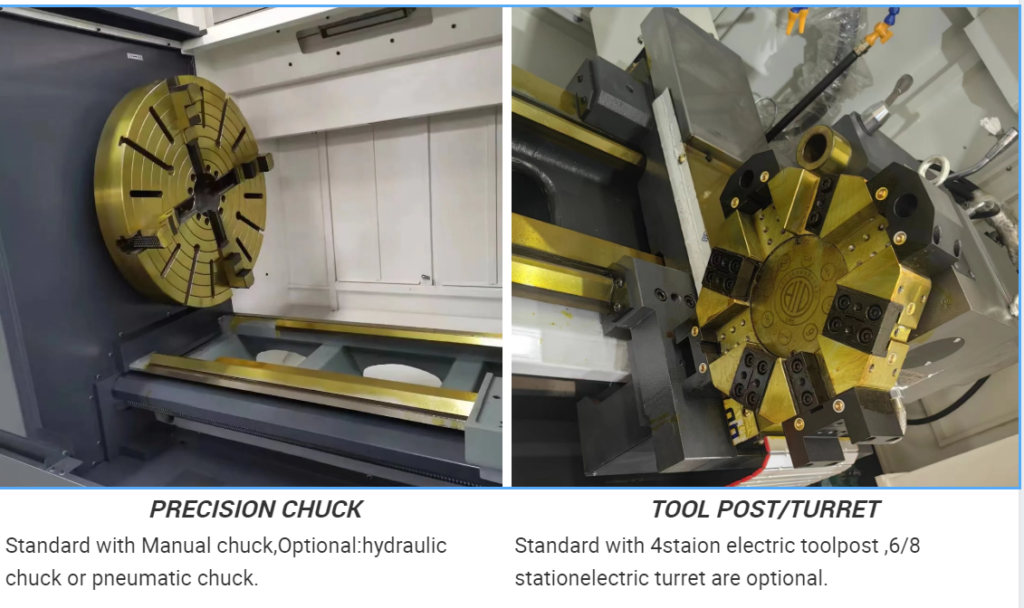

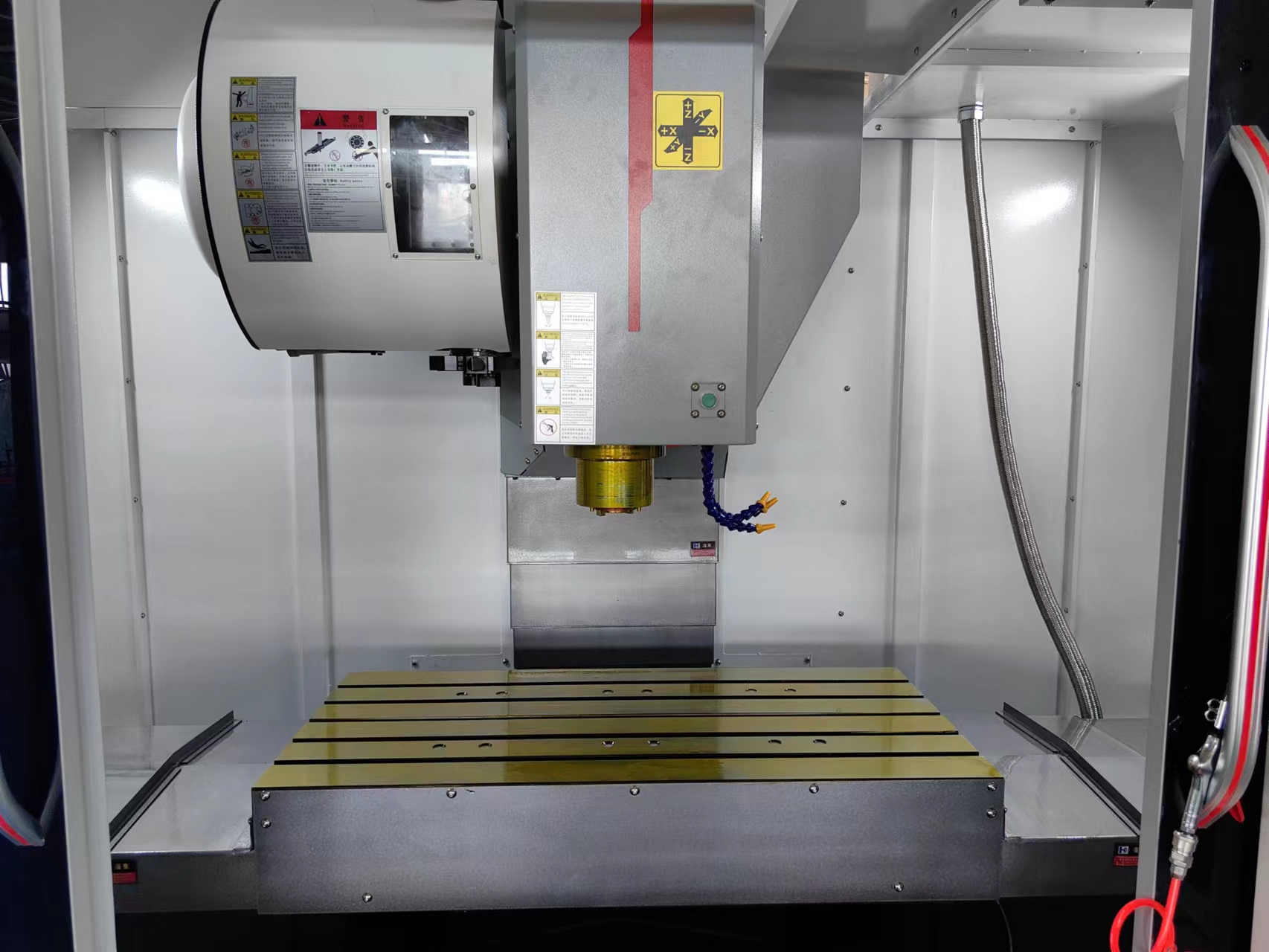

The feed axis of the machining center is controlled by X, Y, and Z coordinates, and the spindle is driven by a servo motor. The tool magazine has a capacity of 16 bamboo hat tool magazines. It can achieve one-time clamping of various complex parts such as discs, plates, shells, cam molds, etc. It can complete various processes such as drilling, milling, expanding, comparing, tapping, etc. It is suitable for the production of multiple varieties of small and medium-sized batch products, and can demonstrate its superiority when processing complex and high-precision parts.

- Main structural features

- The main basic components such as the base, sliding seat, workbench, column, and spindle box are made of high rigidity cast iron structure,There are reinforcing ribs with a mesh structure distributed internally, ensuring the high rigidity and flexural and seismic performance of the foundation components; The basic components are molded with resin sand and undergo aging treatment to ensure the stability of the machine tool’s long-term use accuracy and provide a guarantee for the stability of the machine tool’s performance.

- The X, Y, and Z direction guide rails are all high rigid roller linear guides,The Z-axis has a 4-slider structure, paired with automatic forced lubrication, The frictional resistance of movement is extremely small, without low-speed crawling phenomenon, and the machine tool has high accuracy and lifespan;

3.X. The Y and Z directions are fed using large pitch, high-precision, and high-strength ball screws, with high feed speed; The servo motor utilizes an elastic coupling to be directly connected to the screw, and the feed servo motor directly transfers power to the high-precision ball screw, ensuring the positioning accuracy of the machine tool;

4.Adopting famous Taiwanese brand high-speed, high-precision, and high rigidity

spindle units, with strong axial and radial bearing capacity, and a rotational speed of up to 8000rpm;

- The spindle can be equipped with a high-performance temperature control system to take away the heat generated by the spindle,Keeping the temperature of the spindle unit in balance with the room temperature greatly reduces the impact of thermal deformation on the spindle rotation accuracy and prolongs the service life of the spindle;

- The external protection of the machine tool adopts a fully enclosed mechanism design, which is safe and reliable;

- The machine tool operating system is designed based on ergonomic principles, and the operation box is set independently,Close to the operator, equipped with a handheld electronic handwheel operation box for easy knife alignment;

- Adopting advanced centralized automatic lubrication devices,Regular and quantitative automatic intermittent lubrication, stable and reliable operation;

- The machine tool is equipped with a Fanuccontrol system,Fully functional, easy to operate, stable and reliable accuracy;

- Optional chain chip conveyor for automatic chip removal;

Reviews

There are no reviews yet.